High-quality, high-performance lubricants help the skies soar

Today, aerospace activity is on the rise. China is rapidly increasing the number of space flights it conducts each year, and companies such as SpaceX, Virgin Galactic, and Blue Origin are now conducting regular commercial space launches.

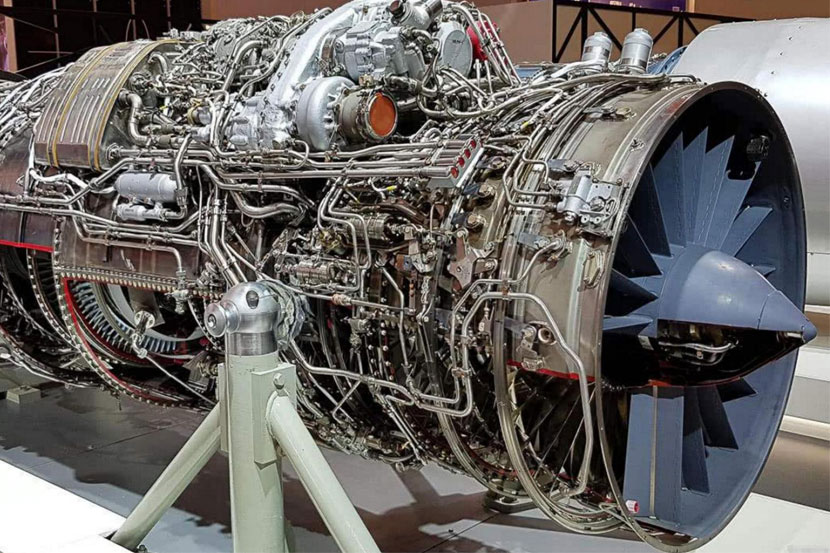

All of these activities rely on advanced engine and propulsion technologies: components that are required to operate under fairly extreme conditions while meeting stringent specification requirements.

Norbert® performance lubricants, including premium products certified to military standards (MIL-SPEC), have been tested and experimented with in aerospace applications since the early 1960s. As a result, these products have a reputation for providing quality and effective solutions.

Norbert® performance lubricants offer many advantages in aerospace applications, including

Ability to maintain performance over a wide temperature range: -70°C to 399°C (-100°F to 750°F)

Physical properties that are stable and do not readily change over time

Excellent friction-reducing properties for longer service life

Suitable for most metals, elastomers, plastics, paints and finishes

Non-toxic, non-flammable, inert and non-volatile, NSF H-1 approved for lubrication in food processing where incidental contact with food is possible (e.g., commercial airline kitchens)

Norbert® lubricants are now used in a variety of aerospace applications, including:

- Oxygen system connections, valves, regulators and seals

- Liquid fuel rocket engines and ground support systems

- Wind turbines

- Instrumentation, gyroscopes and balance rings

- Seals, valves and pneumatics

- Bearings

- Guide rods and ball screws

- Electromechanical brakes

- Engine auxiliary gearbox splines

- Anti-friction brackets and engine oil tanks

- Insulating lubricants for sealing electrical joints

- IR sensors and optics

Lubricants that reduce the frequency of aircraft maintenance

In commercial, corporate and military aerospace applications, Norbert® performance lubricants reduce maintenance requirements, improve safety and reliability, and meet a wide range of military specification (MIL-SPEC) requirements.

Norbert® greases help reduce overall operating costs by eliminating the need to re-lubricate components, thereby reducing equipment downtime and extending maintenance intervals.

High Performance Lubricants for Space Applications

Norbert® performance lubricants are ideal for the harsh conditions of spacecraft. These high performance greases and lubricants provide consistent, superior and long-lasting performance even when exposed to extreme high and low temperatures, extreme pressures and harsh environments.

Perfluoropolyether (PFPE) lubricants and greases offer excellent performance for aerospace and satellite applications, including

Ability to maintain performance over a wide temperature range: -70°C to 399°C (-100°F to 750°F)

Physical properties that are stable and do not change easily over time

Resistance to shock and vibration, high temperature and pressure, and also to reactive chemicals in rocket fuel and oxidizers

Resistant to radiation

Very low vapor loss under vacuum conditions at high altitudes, in celestial orbit or during outer space flight

To meet the challenges of the future, new additives are incorporated into Norbert® greases and lubricants to deliver superior performance, even under extreme space conditions.

Relevant space and satellite applications include

- Bearings

- High-speed bearings

- Synchronous motor bearings in gyroscopes

- Thrust and vector control bearings

- Seals used in valves and pumps

- Joints and joints in space suits

- O-rings used in engines and hydraulic systems

- Oxygen systems

- Rover and spacesuit valves and pump packing seals

- Mechanical seals and joints

- Rocket engine assemblies

- Liquid fuel turbines

- Balance rings

- Pumps

- Reduction gears

- Valves in contact with fuel/oxidizer

- Threaded fasteners

- Metal couplings

- Valve seals and threads